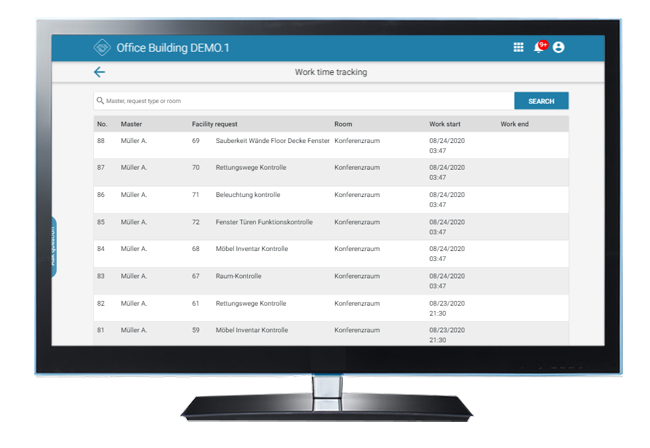

Web service of engineering monitoring of technical conditions of enterprise equipment, building’s engineering systems for life support, safety systems, power station, production lines, and any kind of aggregates with online access to data 24/7.

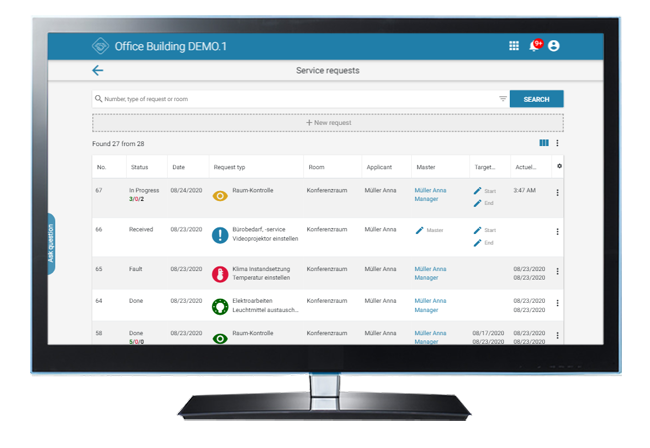

- Automated dispatching control system online.

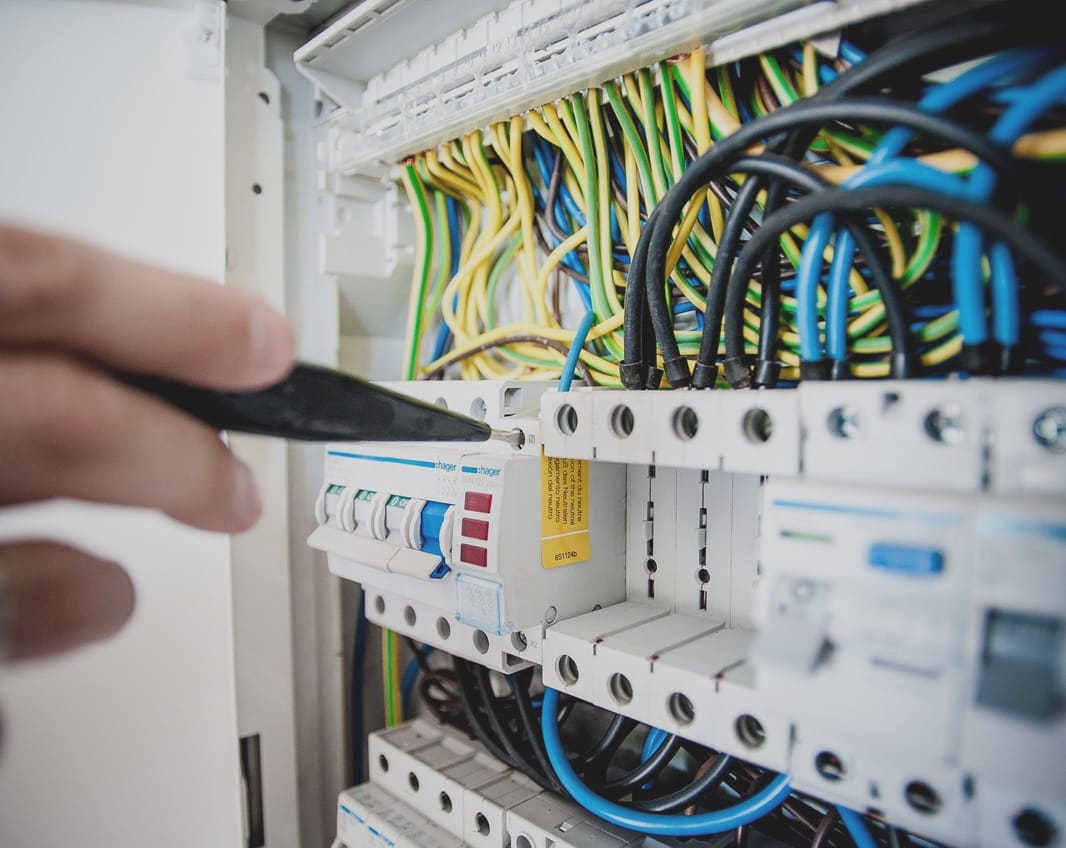

- Data collection from controllers, equipment sensors and instrumentation is a simple and cost-effective newest SCADA solution.

- Addressable notification of on-duty engineers, technicians about the deviation of parameters, and occurrence of emergency situations.

- Online control of emergency situations, maintenance, and service work.

- Hardware integration with engineering systems and production equipment using standard protocols and any communication channels.